CCM Copper Molds

Copper molds are core components of crystallizers for continuous casting to solidify molten steel into billets or slabs in different profiles and sizes. Kinflink provides a wide range of high-quality copper molds as well as crystallizer assemblies and other CCM spare parts to customers worldwide.

Mold Tubes

Mold Plates

Mold Assemblies

Mould assemblies are the core equipment for continuous casting

We produce round, square, rectangular, and beam blank mould assemblies of different sizes with the material of stainless steel and carbon steel.

We have vertical and curved types in structure. The precision of mould assemblies is guaranteed as the forged stainless water jackets are produced by extrusion while assembled water jackets are machined by high-precision CNC machines.

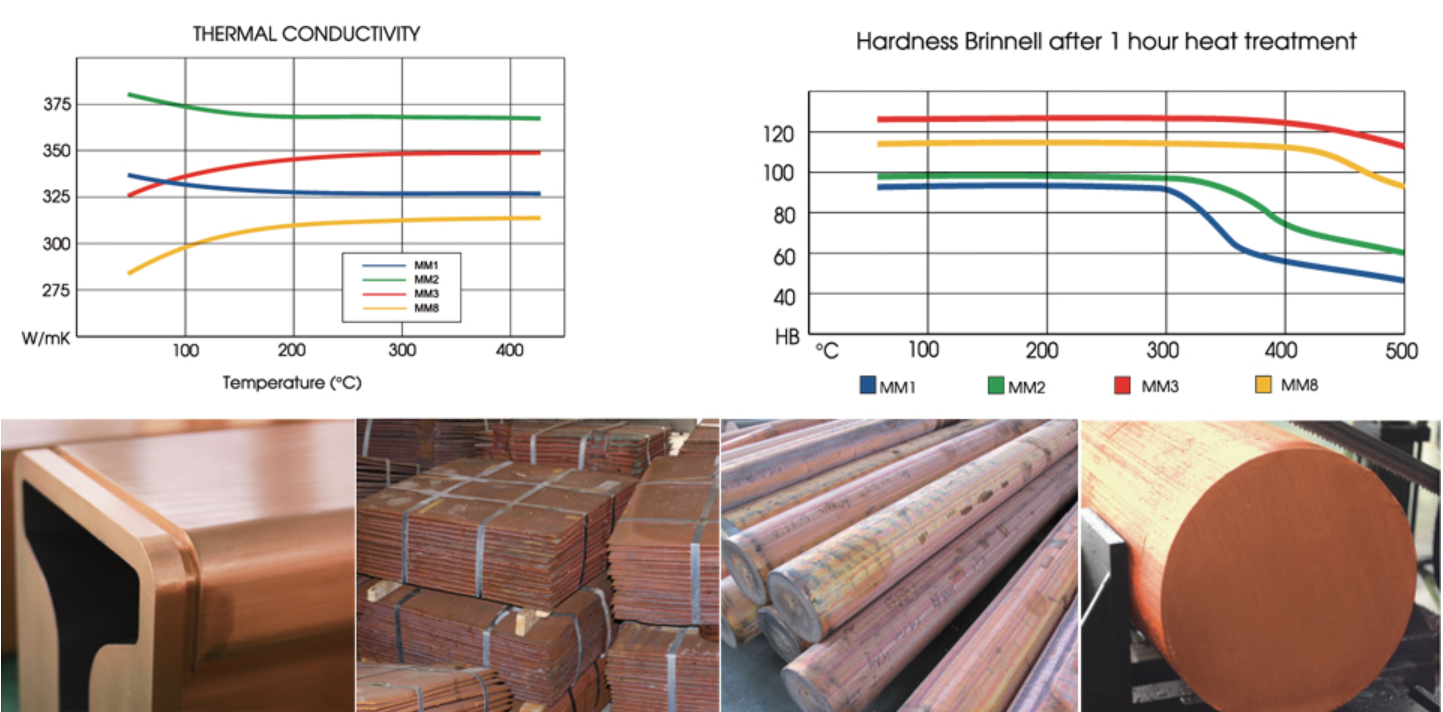

Material We Used

TP2 is a kind of material is selected by most of the steel plants.It shows excellent heat-proof and antifatigue property under high temperature and it has good processing property.

CuAg0.1 is adding 0.08%-0.12% silver during copper ingots melting will increase the recrystallization temperature of copper by 100C, which will increase the heat stress and anti-abrasive property of copper mould tube interior surface, showing better heatresistant property than TP2.

Cu-Cr-Zr is a kind of copper allys which can be normalized by time.It has excellent mechanical property under both room temperature and hight temperature. It has hight heat conductivity, melting point, antifatigue and anti heat stress properties. Their outstanding features make it different from the previous copper alloys. It combines all good properties together. But compared with other copper alloys, Cu-CrZr is difficult to be formed with higher products costs.